The Green Deal and Fit for 55 regulation frameworks are pushing the 2030 and 2050 deadlines closer.

Time, lack of clarity in regulations and a constantly changing landscape of new fuels and technologies are making decarbonization the most important priority and a crucial opportunity for Shipowners.

Ecospray is continuously working on decarbonization, following different ways:

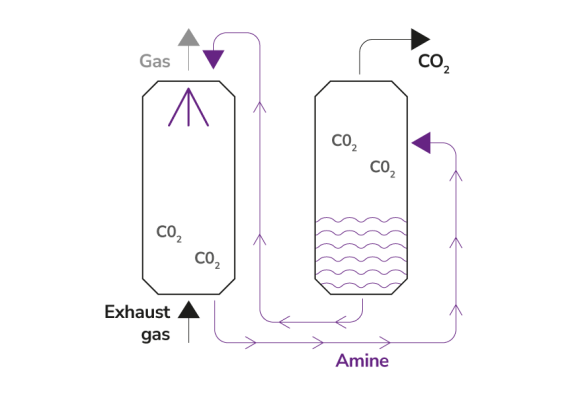

This technology, based on amine chemical absorption, is conceived for CCS in marine onboard application. Widely used for land-based applications, Ecospray worked on the marinization of the technology, with the main goal of reducing the dimensions and complexity of the system. Considering the power consumption, another particular focus is the process optimization, using the thermal energy available on board.

CO2 is absorbed by the amine solution and, during the process, the amine solution is regenerated by stripping the CO2 out of it. Once separated, the CO2 is then liquefied and stored in specific cryogenic tanks onboard.

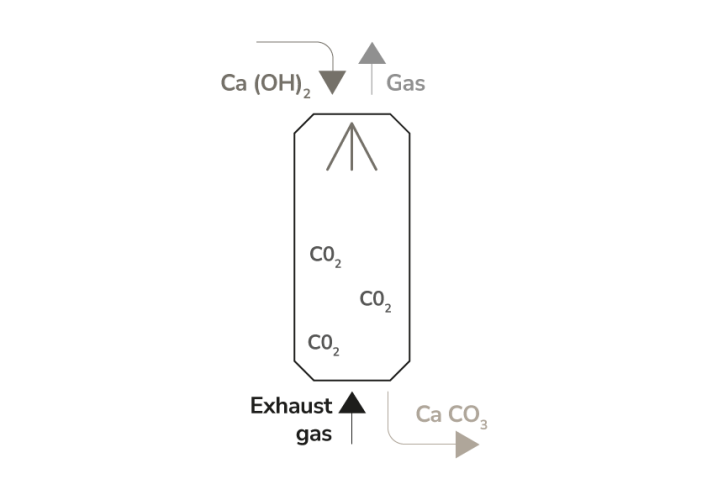

The CapLab laboratory was established jointly by Ecospray and the Department of Civil, Chemical and Environmental Engineering of the University of Genoa with the aim of developing electrochemical cells for CO2 capture, the production of energy and the promotion of the hydrogen carrier.

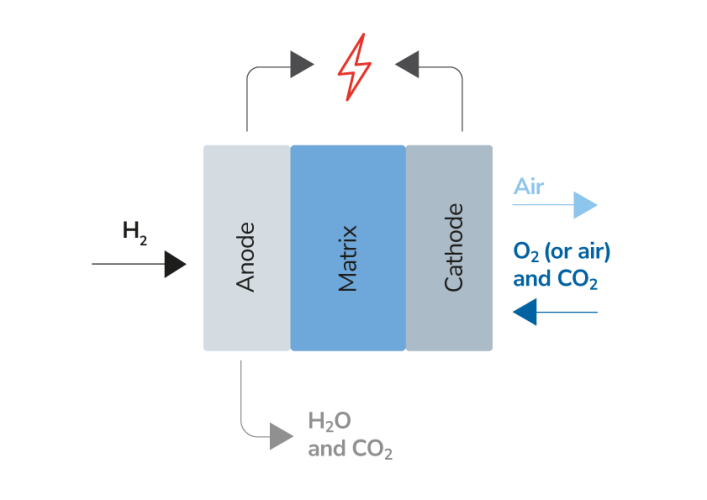

The new laboratory is focused on the development of molten carbonate fuel cells, a technology that allows the capture of carbon while producing energy, hence considered strategic in the context of the energy transition, precisely for its ability to capture CO2 from exhaust fumes and generate clean energy.

CapLab is the laboratory dedicated to the development of new technologies to promote decarbonization and energy transition, established jointly by Ecospray and the University of Genoa.

The technology in the R&D phase at CapLab allows, through fuel cells and electrolyzers, to capture the CO2 emitted from other processes and, as a secondary benefit, to produce energy, effectively promoting the transition to a CO2-free future.

Do you want to know more and stay updated with our Carbon Capture Technologies?